Customized Power Inductor

The power inductor is an inductor with a large current passing through it, comparing traditional inductor, it’s with small size, high Q value, low impedance, high efficiency, low temperature rise, customized.

When design the power inductors, engineer pay attention to optimizing the click structure, to guarantee the internal magnetic field of products becomes more uniform, and the power inductors winding wires must meet requirements. The power inductors are popular used in DC-DC (power module) loops to adjust power output, stabilize current and store energy, such as switching power supplies, green energy vehicle charging piles.

We, Coilcore have a experts team on power inductors design, which could meet different customers electronic parameter request. Following several projects show:

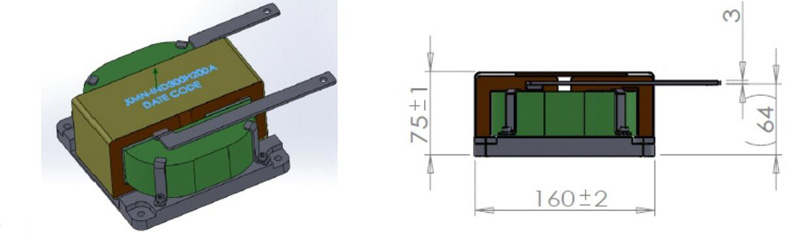

Project 1: Hydrogen Fuel Boost Inductor

|

superiority |

Electronic Parameter |

|

Customized structure, minimized size, installation space saving. |

Peak Input Current: 100A |

|

Multi-strand Litz wire winding, excellent softness. |

RMS Input Current: 70A |

|

High temperature & pressure resistance. |

Working Frequency: 50KHz |

|

Powder coated core, ultra-low core loss. |

Inductance: 125uH |

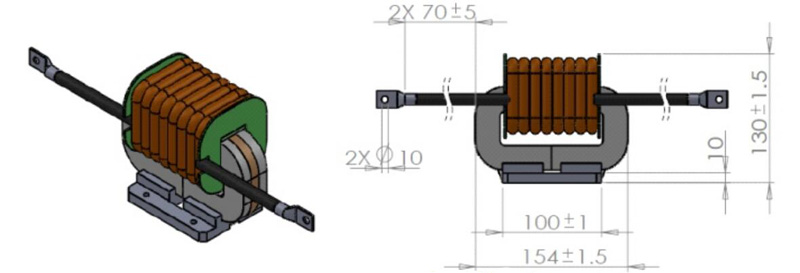

Project 2: Hydrogen Fuel Boost Inductor

|

superiority |

Electronic Parameter |

|

Flat structure design, meet installation height request. |

Voltage Input: 120V |

|

Bracket fixed, easy installation. |

Voltage Output: 500V |

|

Copper foil winding, flat wire terminals |

Peak Input Current: 220A |

|

Good heat dissipation performance |

RMS Input Current: 200A |

|

Low core loss. |

Working Frequency: 7KHz |

|

Low temperature rise. |

Inductance: 300uH |

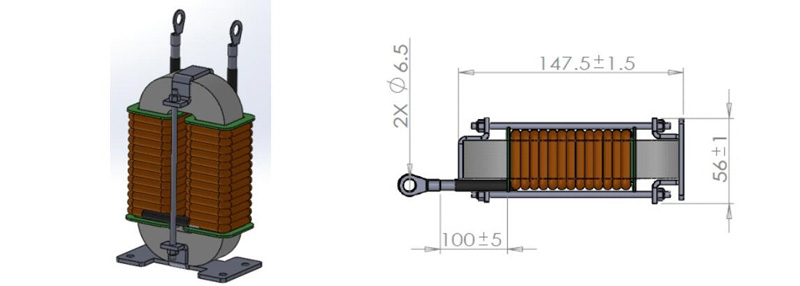

Project 3: 185KW, MMC (Modular Multilevel Converter) Bidirectional (photovoltaic) charging - front bridge arm inductance

|

superiority |

Electronic Parameter |

|

Customized structure, minimized size, installation space saving. |

Voltage Input: 200V |

|

Voltage Output: 700V |

|

|

Multi-strand Litz wire winding, excellent softness. |

Peak Input Current: 100A |

|

RMS Input Current: 70A |

|

|

High temperature & pressure resistance. |

Working Frequency: 50KHz |

|

Powder coated core, ultra-low core loss. |

Inductance: 125uH |

Project 4: 10KW locomotive fire-free loopback DC/DC resonant inductor

|

superiority |

Electronic Parameter |

|

Multi-strand Litz wire winding, ultra-low core loss, terminal welded directly. |

AC Current Input: 40A AC |

|

Input DC Bias: 26A DC |

|

|

The bridge arm inductor is designed with a vertical heat dissipation aluminum base plate to save horizontal space. |

Peak Input Current: 100A |

|

Resistance: 7m OHMS |

|

|

Ultra-thin nanocrystalline ribbon cores reduce size and improve performance. |

Working Frequency: 10KHz |

|

Pressure resistance: 2500V DC/ 60S |

Anterior :

The Inductive Power Supply Current Transformer - Energy Harvesting CoilsPróxima :

Rogowski coilCategorías

Nuevo blog

Llama a :

Llama a :

Tel : +86-20-85649266

Fax : +86-20-85649263

Envíanos un correo electrónico :

Envíanos un correo electrónico :

Correo electrónico : derful@coilcore.com

Dirección :

Dirección :

A402 Zhuangyuangang Industry Park, No.186 Qishan Road, Tianhe District, Guangzhou 510663

© Derechos de autor: 2026 Guangzhou Amorphous Electronic Technology Co.,ltd. Reservados todos los derechos. 粤ICP备2021057165号

Red IPv6 admitida

Enlaces amistosos:

Precision Air Conditioning wellav syblecode gangyuantech PCB Board eavisionag PLC liantronics kenmold 5gplc Mu Metal Core Manufacturer PLC modules liantronics Customized Filter Supplier tslcd szgilong addbuyplc ifpdtech dtechelectronics sekloadcell naturollsensor smarts-electronics bnttablesocket mbluetech esdled oscymonitor current sensor zhicetemptech benchu-group esdled