Soft Metal Magnetic Cores Material

Currently, in the field of soft magnetic materials, soft metal magnetic powder core is the material with the best comprehensive performance , which is made by pressing and sintering magnetic powder bonded by polymer adhesive.

The soft metal magnetic powder core made by high saturation magnetic induction intensity alloy particles powder, those particle insulation layer is wrapped to increase its electrical resistivity. It can meet the needs of high-frequency use and miniaturization, widlly used in different occasions.

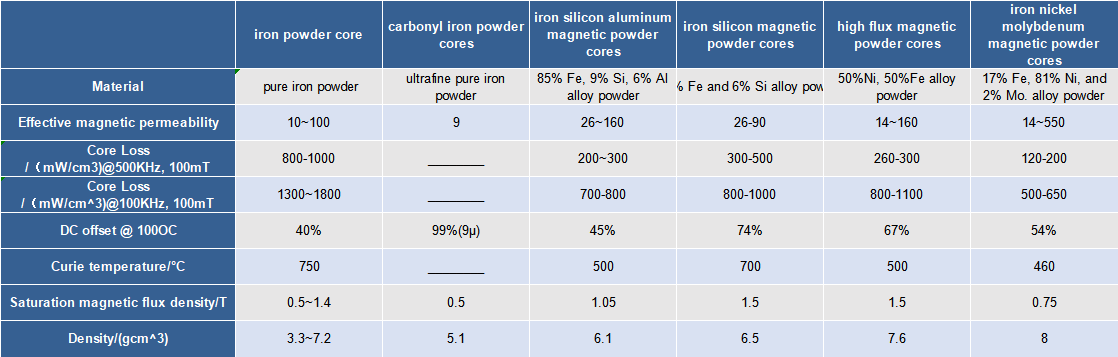

Soft metal magnetic powder cores can be divided into iron powder cores, carbonyl iron powder cores, iron silicon aluminum magnetic powder cores, iron silicon magnetic powder cores, high flux magnetic powder cores, and iron nickel molybdenum magnetic powder cores. Here let’s have a brief introduce of them:

Iron powder core

The iron powder core are made of pure iron powder, coated with surface insulation and then mixed&pressed with organic adhesive. The iron powder cores are popular in energy storage inductors, EMI noise filters, DC output/input filters, etc.

carbonyl iron powder cores

Carbonyl iron powder core: made of ultrafine pure iron powder, with excellent magnetic bias characteristics and good high-frequency adaptability. Its DC bias characteristics are far superior to other magnetic powder cores, making it an ideal material for manufacturing high-frequency switch circuit output chokes and resonant inductors.

iron silicon aluminum magnetic powder cores

Iron silicon aluminum magnetic powder core is the most cost-effective and widely used alloy powder core, made of 85% Fe, 9% Si, 6% Al alloy powder, suitable for power correction PFC inductors, energy storage filter inductors, etc.

iron silicon magnetic powder cores

The iron silicon magnetic powder core is made of alloy powder of 94% Fe and 6% Si, suitable for high current anti current devices, high energy storage power inductors, PFC inductors, etc. It is widely used in new energy fields such as solar energy, wind energy, and hybrid vehicles.

high flux magnetic powder cores

High flux magnetic powder cores have excellent DC bias characteristics, low loss, and high energy storage properties, making them the magnetic powder cores with the highest magnetic flux density. Very suitable for applications with high power and high DC bias, such as dimming inductors, pulse transformers, and power factor correction inductors.

iron nickel molybdenum magnetic powder cores

The iron nickel molybdenum magnetic powder core, also known as the molybdenum molybdenum alloy magnetic powder core, is made of an alloy powder of 17% Fe, 81% Ni, and 2% Mo. It has the characteristics of high magnetic permeability, high resistivity, low hysteresis, and low eddy current loss. In the field of alloy powder cores, iron nickel molybdenum magnetic powder cores have the lowest loss and also have the best temperature stability. Suitable for use in high-Q filters, boost/buck inductors, power factor correction PFC inductors, filters.

Categorías

Nuevo blog

Llama a :

Llama a :

Tel : +86-20-85649266

Fax : +86-20-85649263

Envíanos un correo electrónico :

Envíanos un correo electrónico :

Correo electrónico : derful@coilcore.com

Dirección :

Dirección :

A402 Zhuangyuangang Industry Park, No.186 Qishan Road, Tianhe District, Guangzhou 510663

© Derechos de autor: 2026 Guangzhou Amorphous Electronic Technology Co.,ltd. Reservados todos los derechos. 粤ICP备2021057165号

Red IPv6 admitida

Enlaces amistosos:

Precision Air Conditioning wellav syblecode gangyuantech PCB Board eavisionag PLC liantronics kenmold 5gplc Mu Metal Core Manufacturer PLC modules liantronics Customized Filter Supplier tslcd szgilong addbuyplc ifpdtech dtechelectronics sekloadcell naturollsensor smarts-electronics bnttablesocket mbluetech esdled oscymonitor current sensor zhicetemptech benchu-group esdled