PFC Inductors Working Principle & Main Type

PFC inductors are widely used in switching power supplies because they improve power factor, power efficiency, electromagnetic interference, and greatly enhance circuit stability.

The working principle of PFC inductor is that when the current passes through it, the magnetic field generated will reduce the rate of change of the current, thereby reducing high-order harmonics in the circuit, smoothing the current in the circuit, reducing ineffective power loss, and improving the power factor of the power supply.

When the current passes through PFC inductor, the inductor will convert some electrical energy into magnetic energy for storage. When the direction of the current changes, the stored electrical energy will be released and converted into electrical energy for the circuit to continue working.

Based on experience, once the power supply power is greater than 75W, it's need to increase the PFC inductance, otherwise the high-order harmonics are too high to test passed.

PFC inductors are divided into passive PFC inductors and active PFC inductors.

The low price passive PFC inductor has a simple structure, PF value between 0.7 and 0.8, which basically eliminated by the market.

The active PFC inductor with advantage wide input voltage, small size & weight, PF value>0.9, which are the mainstream product in the market.

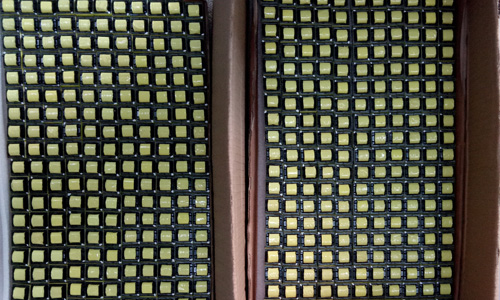

The commonly cores for Active PFC inductor including ferrite core and iron powder cores.

The ferrite core for PFC inductors are mainly PQ series and RM series, require open air gap and need to meet basic insulation requirements of safety regulations . Generally, the ferrite core PFC inductors with two windings, main windings with many coils wound but few coils in the secondary winding. The voltage resistance of the the main winding to the secondary winding should meet 1750VAC. The final turns ratio and winding turns based on real request.

The iron powder core PFC inductors usually have one main winding (secondary set in the PFC chip), simple winding but large number of winding turns.

Few iron powder core PFC inductors have two windings, which used to directly replace power ferrite core PFC inductors (PFC chips remain unchanged). It’s usually used as research and development debugging or transitional products because of the high cost &non-conducive production.

Anterior :

The Q Value For Transformers and InductorsPróxima :

Talk About CMC and EMCCategorías

Nuevo blog

Llama a :

Llama a :

Tel : +86-20-85649266

Fax : +86-20-85649263

Envíanos un correo electrónico :

Envíanos un correo electrónico :

Correo electrónico : derful@coilcore.com

Dirección :

Dirección :

A402 Zhuangyuangang Industry Park, No.186 Qishan Road, Tianhe District, Guangzhou 510663

© Derechos de autor: 2026 Guangzhou Amorphous Electronic Technology Co.,ltd. Reservados todos los derechos. 粤ICP备2021057165号

Red IPv6 admitida

Enlaces amistosos:

Precision Air Conditioning wellav syblecode gangyuantech PCB Board eavisionag PLC liantronics kenmold 5gplc Mu Metal Core Manufacturer PLC modules liantronics Customized Filter Supplier tslcd szgilong addbuyplc ifpdtech dtechelectronics sekloadcell naturollsensor smarts-electronics bnttablesocket mbluetech esdled oscymonitor current sensor zhicetemptech benchu-group esdled