Iron Powder Core

With the development of miniaturization, thinning and high frequency of electronic equipment, Fe-Si and Fe-Si-Al soft magnetic powder cores are more and more popular used in emerging fields such as new energy vehicles, charging piles, photovoltaic inverters, etc. Today, let's discuss about such iron powder core:

What’s Iron Powder Core?

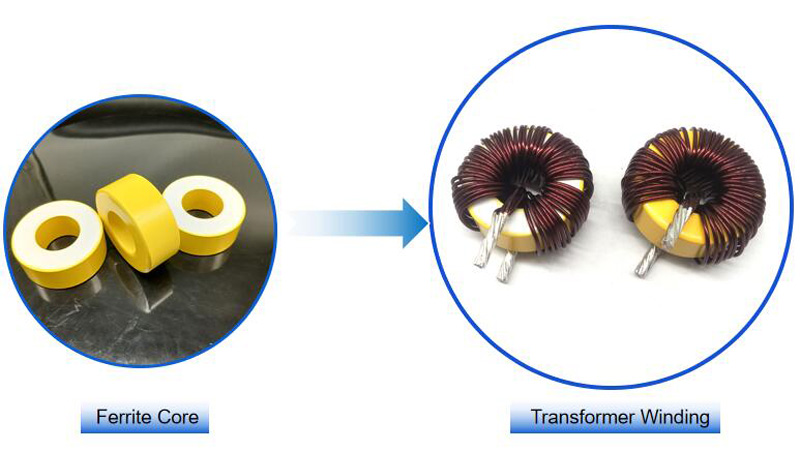

Iron powder core is a soft magnetic material, which composed of carbon-based ferromagnetic powder and resin carbon-based ferromagnetic powder. Attracted by its competitive price, iron powder cores are still the most widely used magnetic powder cores in the market.

What’s the work frequency of iron powder core?

The traditional iron powder core is Iron-Silicon-Aluminium alloy core, which mainly work at 20KHz~200KHz. Comparing the ferrite core operating in the same frequency bank, the silicon-aluminium alloy core have a higher saturation magnetic flue density, better DC superposition characteristics, closer to zero magnetic striction coefficient, no noise during operation, good frequency stability, and high performance-price ratio. It's widely used in high frequency electronic components. The disadvantage is that the non-magnetic filling not only produces magnetic dilution, but also makes the magnetic flux path discontinuous, and local demagnetization field leads to the decreased of magnetic permeability. Thus, it's mainly used in low request of Bm.

Different from the traditional iron-silicon-aluminum magnetic powder core, the latest high-performance iron powder core is made of pure iron powder coated with an insulating layer. The amount of binder is very small, and the magnetic flux density is greatly improved. They operate in the low to mid frequency range below 5kHz, typically a few hundred hertz.

What is the saturation magnetic flux density of an iron powder core?

What is the difference between FeSiAl magnetic core and iron powder core?

The FeSiAl magnetic core is composed of 9% AI, 5% Si, and 85% iron. It is often used to replace the iron powder core. The loss of the iron silicon aluminum core is 80% smaller than that of the iron powder core, and its saturation magnetic induction is about 1.05T; the magnetic permeability is 26~125; the magnetostriction coefficient is close to 0, and there is no Noise generation; DC bias capability higher than MPP; cost-effective. Mainly used for AC inductors, output inductors, line filters, power factor correction circuits. It can also be used as a transformer core instead of a ferrite with an air gap. Commonly used black paint, the ui value is mainly in: 26/60/75/90/125

The magnetic permeability of the iron powder core is 10~100, and the DC superposition performance is good, but the loss is high at high frequency. Iron powder cores are generally suitable for inductors with small inductance and high current resistance. Iron powder core features:

1. Strong saturation induction, can work in high current environment;

2. Stable performance, effective magnetic permeability has excellent frequency characteristics;

3. It has high temperature characteristics and is suitable for the temperature range of -65~+125;

4. The ring structure has low electromagnetic radiation and saves shielding materials;

5. The iron powder core has better noise suppression and absorption capacity, which is better than the ferrite core.

Categorías

Nuevo blog

Llama a :

Llama a :

Tel : +86-20-85649266

Fax : +86-20-85649263

Envíanos un correo electrónico :

Envíanos un correo electrónico :

Correo electrónico : derful@coilcore.com

Dirección :

Dirección :

A402 Zhuangyuangang Industry Park, No.186 Qishan Road, Tianhe District, Guangzhou 510663

© Derechos de autor: 2026 Guangzhou Amorphous Electronic Technology Co.,ltd. Reservados todos los derechos. 粤ICP备2021057165号

Red IPv6 admitida

Enlaces amistosos:

Precision Air Conditioning wellav syblecode gangyuantech PCB Board eavisionag PLC liantronics kenmold 5gplc Mu Metal Core Manufacturer PLC modules liantronics Customized Filter Supplier tslcd szgilong addbuyplc ifpdtech dtechelectronics sekloadcell naturollsensor smarts-electronics bnttablesocket mbluetech esdled oscymonitor current sensor zhicetemptech benchu-group esdled